Blog

Home » How to clean and maintain ESD flooring

How to clean and maintain ESD flooring

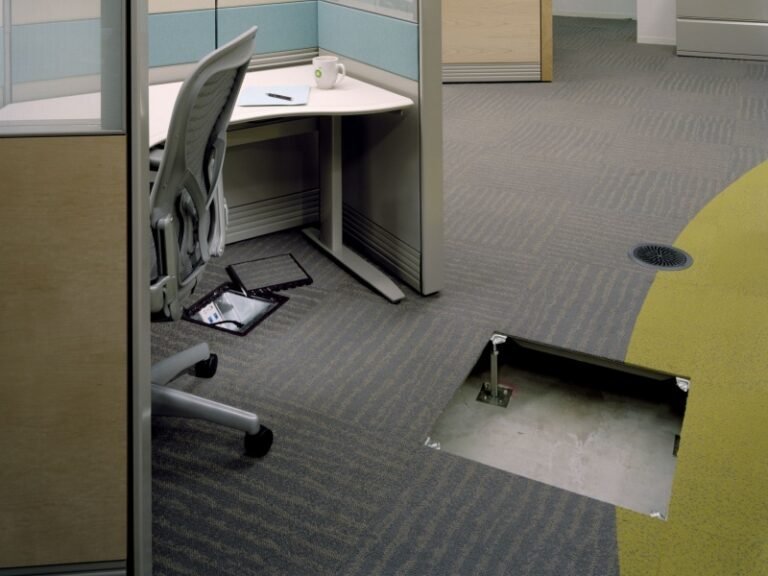

ESD flooring, especially PVC antistatic flooring, is an essential solution in environments sensitive to static electricity, such as server rooms, clean rooms, laboratories, and production areas. Understanding the proper tools and techniques for maintaining ESD flooring can extend its lifespan and ensure it performs at its best. Below, we explain some tools and tips for effectively maintaining ESD flooring.

Understanding ESD Flooring Types

ESD tiles: ESD tiles are crafted with PVC particles that form a conductive grid at the interface, ensuring permanent antistatic properties. Common tile sizes include 600x600mm, 610x610mm, and 900x900mm, with thicknesses of 2.0mm, 2.5mm, and 3.0mm.

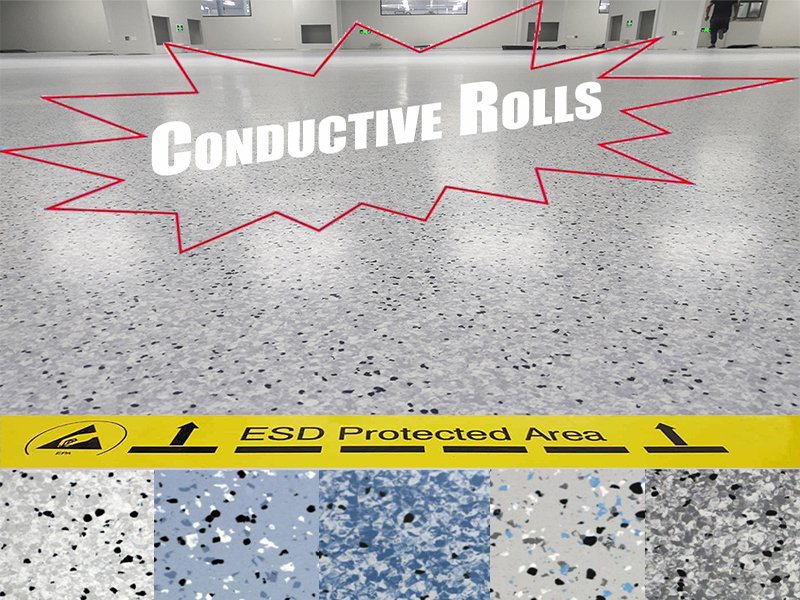

ESD Roll Flooring: Rolls typically come in sizes of 2x20m with a thickness of 2.0mm, allowing for large surface coverage. When cutting rolls to fit the installation area, it’s advisable to allow extra width for trimming, ensuring a seamless, uniform finish across the floor.

Preparation Tools

Dolphin Knife for Cutting and Shaping: The Dolphin Knife is ergonomically designed and accommodates both straight and hook blades, making it safe and easy to handle. It’s the ideal tool for precise cutting, especially when customizing the fit of ESD flooring in intricate spaces.

Floor Preparation Before Installation

Ensure the subfloor is level, dry, and free of dust and debris.

Conductive Foil (Copper or Aluminum): To ensure optimal conductivity, a layer of conductive foil with a thickness of 0.01-0.05mm and width of 20-40mm is laid before installation. This helps to establish an effective conductive network throughout the flooring.

Adhesives for ESD Flooring: Reliable adhesives such as M720D, M760D, and M919 ensure secure bonding for ESD flooring. Choose adhesives with a resistance value of less than 10⁴Ω for effective conductivity and lasting adherence.

Maintenance Tools for ESD Flooring

ESD Floor Wax (e.g., M937 and M933): Once the flooring is installed, applying ESD-specific floor wax helps protect the surface, maintain a clean appearance, and enhance the floor’s static dissipative properties. Regular waxing is essential for high-traffic areas to keep ESD flooring in top condition.

Adhesive Remover (M927): If adhesive residue is left on the surface post-installation, M927 adhesive remover is designed to effectively remove all traces without damaging the flooring.

Water-based Degreaser (M925): For areas where oil or grease may accumulate, especially in industrial spaces, M925 degreaser is an ideal solution. Its water-based formula is safe for ESD flooring and efficiently removes oil stains.

Deep Cleaning Solution (M920): For deep cleaning, M920 provides an environmentally friendly option that thoroughly cleans without scratching the floor surface. This cleaner is excellent for periodic maintenance in high-use environments to keep floors looking new and functioning effectively.

Regular Maintenance Tips for Optimal ESD Performance

Routine Sweeping and Mopping: Use non-abrasive tools and avoid harsh chemicals to prevent surface damage.

Scheduled Floor Waxing: Apply ESD-specific waxes periodically to retain the antistatic properties of the flooring and protect it from wear and tear.

Immediate Spill Removal: Address spills promptly, especially liquids that could compromise the flooring’s conductivity or stain the surface.

Regular cleaning and the proper use of ESD-compatible maintenance products can significantly extend the life and functionality of your ESD flooring, ensuring a safe and efficient environment.

By following these tips, you can maintain a static-free workspace that continues to meet industry standards for safety and cleanliness.